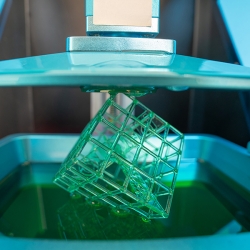

3D Printing

Bomar® oligomers for 3D printing feature a wide range of mechanical properties used to formulate flexible, rigid, or tough inks and resins for unique applications.

Bomar® designs and synthesizes UV/EB oligomer for five core markets: 3D printing resins, nail coating resins, adhesives, industrial coatings, and specialty applications.

We offer a full line of aliphatic and aromatic urethane, polyether urethane, and polyester urethane acrylates and methacrylates, with a strong emphasis on new product development. Each oligomer chemistry is designed and tailored for specific applications and precise performance requirements of the market. In addition, our technical team excels in designing and synthesizing previously unheard of materials.

Our 3D printing oligomers have a wide range of properties, including flexible for tear-resistance, rigid for strength, and toughness for high impact strength.

Nail coatings oligomers are formulated for LED-curable gels, hard gels, soak-off coatings, and long-wear coatings.

Oligomers for adhesives carry properties such as excellent adhesion, flexibility, weatherability, toughness and more.

Industrial coating oligomers have exceptional crosslink density and abrasion resistance making them an excellent choice for plastic, wood, and glass.

Hydrophobic oligomers are often used in specialty applications where moisture barrier and water-resistance properties are needed.

Have questions? Need more information? We're here to help.